ENGINEERING

We utilize our engineering and toolmaking expertise to define the entire process required to complete a finished part to the customer specification. This includes defining the material specification, tooling and equipment required to form the metal stamped part, inspection methods and / or fixtures, secondary operations, and packaging.

Once a part process is defined in our Engineering Master, all facets of the project will be managed through the ERP system. A Work Order, created from the Engineering Master for each production order, is used to purchase material, schedule work, maintain traceability, provide operator instructions, track outside services, and schedule shipping. This allows us to quickly identify potential problems and develop corrective actions before the problems occur.

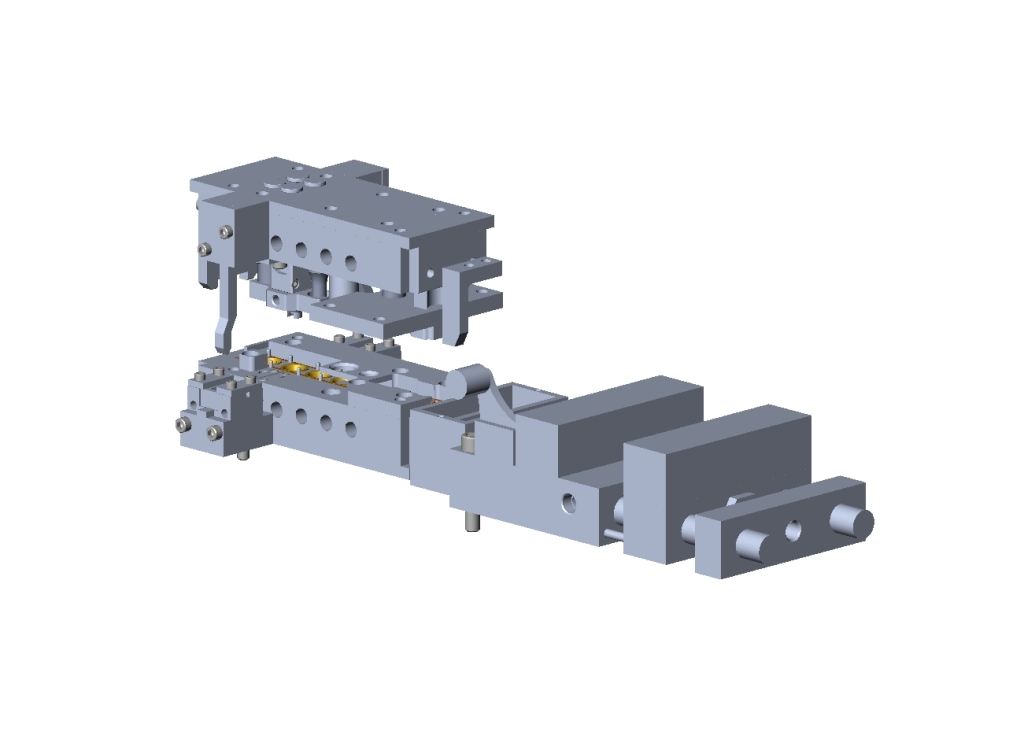

● TOOL DESIGN, BUILD, & DEBUG

ADM Industries designs, builds, and debugs all tooling in-house, utilizing a teamwork approach between Engineering Design, Tool Building, and Quality. Each member of the team is involved in every phase of the project as it progresses from design to debug and then to continual improvements during production.

We utilize SolidWorks, a leader in 3-D solid modeling software, to design our tooling. SolidWorks is capable of importing most common CAD files, allowing us to work with our customer's solid models. Our CNC machining is programmed with CamWorks, a program fully integrated with SolidWorks. This allows us to quickly output CNC code.

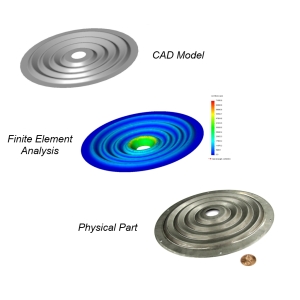

● PRODUCT DEVELOPMENT ASSISTANCE / PROTOTYPING

ADM Industries can be of assistance in any of the phases of product development applicable to a given project. If you have a difficult or unusual metal part, contact us to discuss possible solutions.

Part Design

ADM Industries works with customers that would like assistance with developing their product. We can provide complimentary, initial feedback on the manufacturability of a part design, and then work with the customer's solid model to propose feature changes that would reduce production and / or tooling cost.

Prototyping

Once a part design is finalized, we can provide prototype parts to confirm the design before ordering more costly production tooling and parts.

Short Run Stamping

During the ramp-up stage of a project, we can provide a short run stamping tool that is cost effective for initial smaller production volumes of parts.

Full Scale Production

Once project volume increases, we can design and build a progressive tool to reduce the piece part price. Sometimes, tooling components from the prototyping or short run tooling can be transferred to the progressive tool, reducing the tooling cost.