QUALITY

ADM Industries recognizes that quality in all areas is paramount to providing customer value. We believe that without quality, other components of Customer Value are ultimately irrelevant. Quality is meeting the customer's expectations in every stage of a project, from quoting to delivery.

● QUOTING

A quality quote is one that addresses all potential issues and exceptions to the customer's RFQ. The quote should be delivered in a timely manner and written clearly and professionally. During the quoting phase, we work with the customer to address potential problems and propose possible cost savings. Our quoted piece part price includes perpetual tool maintenance to provide quality parts on an ongoing basis without charging the customer for future tool maintenance.

● ORDER ENTRY

Upon receiving an order at ADM Industries, we verify that the parameters on the purchase order are acceptable and can be completed as requested. Any issues on the purchase order should be dealt with by contacting the customer immediately with possible solutions.

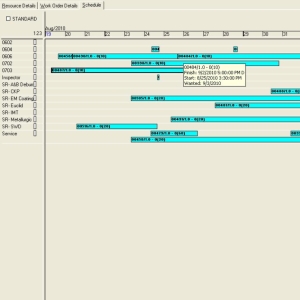

● SCHEDULING PRODUCTION & TOOL BUILD

ADM Industries has systems in place to monitor the schedule and alert customers of any potential delays before they occur. On tool builds, we provide weekly updates of project status to keep the customer informed of progress.

● OUTSIDE SERVICES

We have procedures in place to track parts sent for outside services. We also monitor our supplier base for quality and delivery, ensuring that our suppliers are focused on quality.

● PART QUALITY

The parts must meet the customer's requirements. At ADM Industries, we hold upfront discussions to define the customer's important requirements for a project, including CTQ (Critical to Quality) features, packaging and outsourcing requirements, and material specification. These requirements are used to develop a manufacturing and inspection plan for first article samples and production.

We design and build any inspection fixtures and gaging that are required for a project and utilize SPC (Statistical Process Control), Gage Calibration, PPAP, FMEA, and Gage R&R when appropriate.

● PACKAGING

Packaging is often an overlooked component to quality, but ADM Industries will ensure that proper, cost effective packaging is utilized so that our quality parts maintain their quality during storage and transport to the customer. Some examples of packaging factors to consider are the use of bulk versus hand-packed, custom engineered packaging for fragile or unusual shaped parts, box weight and size, plastic bag liners, dunnage, nested boxes, and rust inhibitors.

● CONTINUOUS IMPROVEMENTS

We at ADM Industries believe that quality extends beyond any given shipment of parts. This means that we continually strive to improve the quality and cost effectiveness of our parts. When a quality issue is brought to our attention by a customer, immediate plans are put in place to mitigate the short term impact to the customer. Plans are also initiated to identify and solve the quality problem with real and aggressive solutions.